Dairy processing

Driven by continuous innovation for over a century, Alfa Laval provides processing equipment that maximizes yield, facilitates easy cleaning, and minimizes waste at every step of dairy processing. Our components help you save on water, energy, and chemicals while meeting the strictest safety and hygiene standards. This way, dairies can make the most of every resource and create top-quality dairy products – with the flexibility and confidence to seize new opportunities in the market.

We help move dairy processing forward

Lower Energy Consumption

Alfa Laval, experts in dairy applications, offers solutions to meet high hygiene and sustainability standards. Their energy-efficient heat exchangers and high-speed separators can cut energy use by up to 30%, optimizing processing and reducing costs.

Cut CO2 Emission

Alfa Laval’s innovative technologies offer a comprehensive approach to sustainable dairy production, helping producers lower energy consumption, cut CO2 emissions, reduce wastewater, and save on chemical use—all without compromising on quality or output.

Reduce Wastewater

Reducing energy, water, and chemical consumption is essential for responsible operations, especially with climate change and water scarcity. Alfa Laval’s dairy processing equipment promotes sustainability, superior hygiene, and optimized processes. Their water-saving technologies can cut water usage by up to 50%

Save on Chemical Use

By choosing Alfa Laval, dairy producers can stay ahead of industry trends, meet sustainability goals, and contribute to a greener future while maintaining efficiency and profitability. Alfa Laval’s technologies reduce chemical consumption and support eco-friendly production in water-stressed areas.

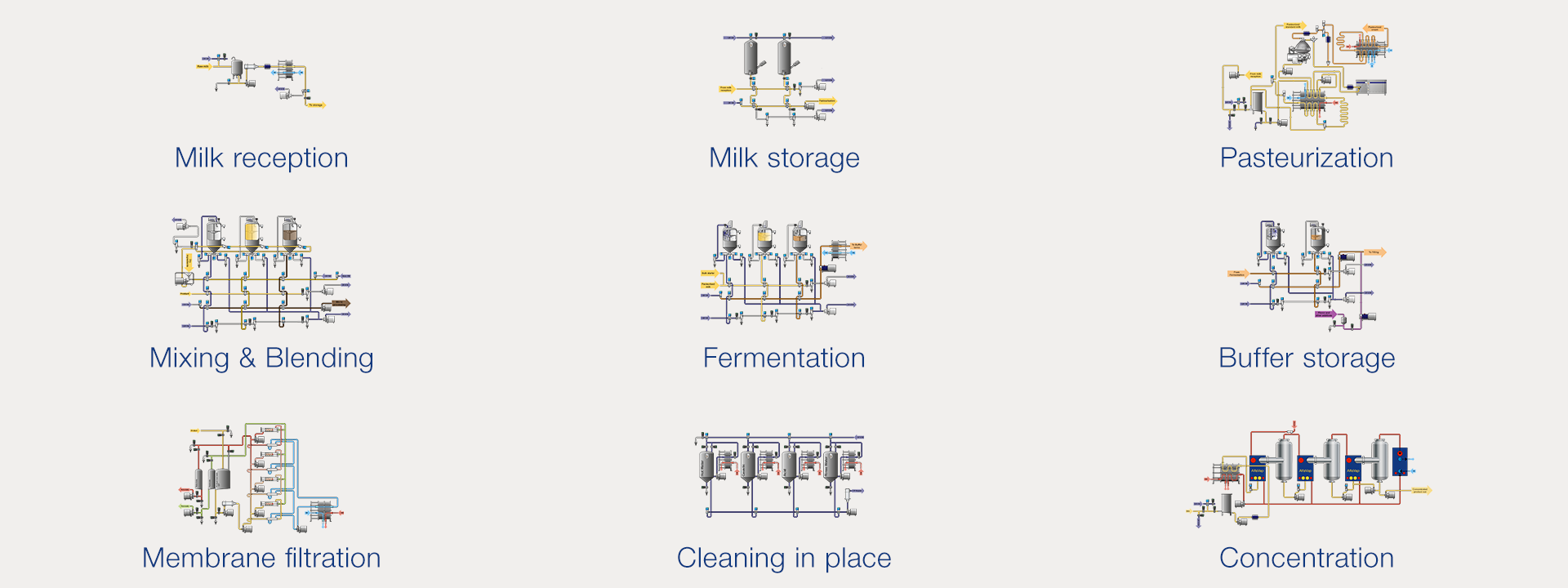

Optimizing every step in your dairy manufacturing process

From raw milk to finished dairy product, Alfa Laval components are designed to get the most out of every processing step. They help in maximizing yield, uptime, and product quality, while bringing power and water consumption to a minimum. Click on the button to view process steps and find highlighted technologies for dairy optimization.

Stay Updated with the Latest in Dairy Processing!

Alfa Laval offers optimal components for diverse dairy applications, highlighting the industry's potential amid global and regional trends. The Near Newsletter provides insights into their offerings and applications in the dairy sector.

Sustainable Diary Case stories

Contherm Max for quality clean-label food production that is reliable and energy efficient

Cedar’s Foods, a leading brand in the natural foods sector, is committed to providing clean-label, preservative-free hummus. Discover how they address reliability and capacity issues in their original SSHEs with Alfa Laval Contherm systems, resulting in five new SSHEs that ensure their hummus is heated, pasteurized, and cooled to perfection.

Casein recovery with higher yield and quality– and maximum uptime

Two of New Zealand’s leading dairy producers have taken a significant step towards enhancing productivity, quality, and uptime by upgrading to Alfa Laval Foodec Hygiene Plus Decanters. Discover how these state-of-the-art decanters are specifically designed for food processing, offering improved efficiency, higher extraction yields, and superior product quality

Increased sustainability of dairy processing lines boosts productivity and profitability

When Yörükog˘lu Süt, a leading Turkish dairy producer, faced challenges with their existing pumps, they turned to Alfa Laval’s Global Alliance Partner, Tetra Pak, for a solution. What started as a routine visit to their Antalya processing plant blossomed into a long-term partnership, delivering increased running time, reduced costs, higher energy savings, and an enhanced sustainability profile.

Safeguard cheese production with 100% cleaning coverage of tank shadow areas

Beritech recommended Alfa Laval top-mounted tank cleaning devices paired with Alfa Laval PlusClean® cleaning nozzles. This combination guarantees 100% tank cleaning coverage, up to 80% savings in water and cleaning media costs, and no product contamination.

Key products

Reduce your environmental footprint

Alfa Laval dairy processing equipment let you do more with less. They empower you to build a sustainable future for your business, while consuming less of the world’s precious resources. See some examples of how our products deliver value below.

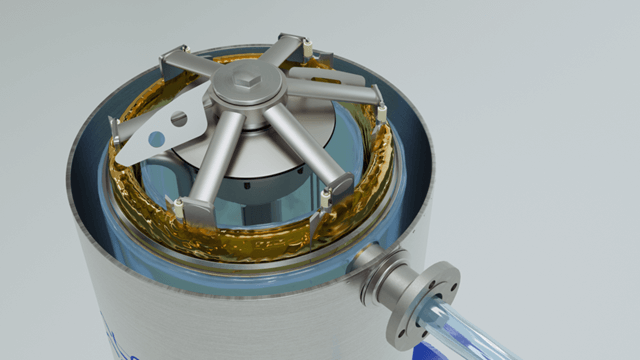

Reduce energy: Hermetic Design & eMotion

With an airtight bowl improving the fluid dynamics, Alfa Laval dairy separators featuring Hermetic Design consume up to 60% less power than non-hermetic alternatives. By creating a near-vacuum around the separator bowl, the Alfa Laval eMotion module can increase energy savings up to 75%.

Reduce water: Thinktop

When it comes to water-saving innovation, the Alfa Laval ThinkTop stands out. When fitted on Unique Mixproof valves, the ThinkTop pulse seat clean function can save up to 95% of water and chemicals during Cleaning-in-Place.

Reduce chemicals: SaniSB

With Sani SB series rotary spray heads, dairy tank cleaning is more efficient than ever. The spray heads create a unique jet pattern, enabling up to 40% savings in time, water, and cleaning media.

Improve yield: Foodec

Purity and yield are the most important parameters during dewheying and dewatering in lactose and casein production. Alfa Laval Foodec decanter centrifuges are ideal for both, enabling up to 25% higher solids handling capacity than similar alternatives.

Service

Professional support right from the start

Backed by experience in servicing equipment for food, dairy & beverage applications, we are ready to support you whenever you encounter problems or wish to discuss upgrade opportunities in your dairy beverage production. We specialize in optimizing CIP programs to reduce water consumption and use of cleaning agents. Thanks to our global network of partners, field service engineers, service centers and spare parts distribution hubs, qualified help and genuine spare parts are always available.

We can support you from the initial installation and commissioning stage, and throughout the entire lifetime of your equipment with preventive maintenance, upgrades, remote monitoring, predictive maintenance, troubleshooting, and more.

Ensure maximal uptime, performance and return on investment. Learn more about the services we offer:

Decanter centrifuge services Hygienic pump services Heat exchanger services

Hygienic tank equipment services Hygienic valve services