ThinkTop® V50

Designed for use in the dairy, food and beverage, and biopharm industries, ThinkTop provides real-time information about valve operating status 24/7 while helping to improve production performance and secure traceability.

The premium valve control unit

ThinkTop is an automated, valve-top pneumatic valve sensing and control unit that provides exceptional surveillance and control of the fluid handling process. Cost-effective and flexible, ThinkTop offers a single sensor solution for Alfa Laval butterfly, single-seat and mixproof valves.

Proven safe and effective

The inherently safe, automated design of the ThinkTop reduces human error and increases production efficiencies – no matter how tough the operating environment. These features contribute to process safety:

- No-touch, set-and-forget sensor system with up to three solenoid valves. Detects both the condition and position of the valve stem with an accuracy of ± 0.1 mm. Set-up parameters are stored but, for greater flexibility and ease of operation, can easily be re-programmed. Because the microchip sensors are moulded directly into the control head, they are less sensitive to the effects of temperature, vibration and pressure shock.

- Individual pre-set tolerance bands. No manual adjustment of feedback sensors is required; individual preset valve tolerance bands eliminate self-adjustment and ensure optimum operational reliability on any Alfa Laval sanitary air-operated valve. This helps prevent contamination and production failure as well as contributes to increased productivity, longer valve service life and more uptime.

- Five feedback signals increase the versatility of the valve sensing and control system and enable comprehensive valve record management data. ThinkTop features four feedback signals: for open position, for closed position, and for up to two integrated seat lifts or two external signals as well as one status signal for a total of five digital PNP/NPN feedback signals.

700 000 valve control units

Engineered for operation in virtually any environment, ThinkTop features a robust, durable and reliable valve sensing and control assembly. Its hygienic design withstands the effects of physical impact, pollution, frost, UV radiation and temperatures up to 85°C. Over the past decade, more than 700,000 units have provided continuous operation in processing plants around the world.

Completely watertight and IP66/IP67-compliant, ThinkTop features the superior GORE™ protective venting technology, which prevents water condensation and the penetration of dust, water and other particles into the control head. The control head can therefore be hosed down with water or cleaning fluid without putting important settings at risk. This contributes to maximum hygiene and effectively eliminates problems associated with corrosion and external contamination.

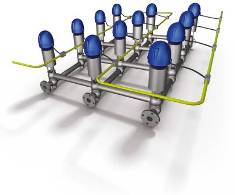

Retrofitting boosts performance

Upgrading older valve automation systems with advanced valve sensing and control technology can significantly lower investment, boost plant performance and cut operating costs. In many cases, the air-operated valve remains the same; only the replacement of the control head interfaces is required. Should upgrading require control head replacement, ThinkTop offers fast return on investment and long-term savings on operating and maintenance costs.

Caption: Upgrading increases reliability while lowering operating costs.

Product benefits

- Increases production efficiencies

- Cost-effective

- Flexible

Product catalogue

How it works

Construction

The ThinkTop sensing and control unit is a uniform modular control head that consists of a proven no-touch, set-and-forget sensor system with light-emitting diodes (LEDs), solenoid valves and valve control sensor board for connection to any PLC (Programming Logic Controller) system.

Operating principle

Inside the ThinkTop control head, the sensor system accurately detects valve stem movement, the valve position at any given time, with an accuracy of ± 0.1mm through the use of microchip sensors. To locate the current valve position, sensor chips inside the sensor board calculate the angle between the axial magnetic field produced by an indication pin mounted on the valve stem.

The sensor system receives signals from the PLC system to open or close the valve and transmits feedback signals on the main valve or seat lift position and condition back to the PLC system.

Up to three solenoid valves convert the sensor signals from electrical current into mechanical energy to open or close the air-operated valve, using the physical stimulus of an indication pin mounted on the valve stem.

Manual hold override enables valve operation during commissioning or maintenance without requiring assistance from plant operators and plant automation. Air throttling of the inlet/outlet makes it possible to slow the opening or closing of the valve thereby preventing pressure shocks and water hammer.

Possibility to customize each control head with an individual tolerance band to detect any deviation in the opening/closing of the valve and seat lift. This boosts productivity and effectively prevents operating errors.

LEDs conveniently display main valve, seat lift position, solenoid activation, setup and local fault indication and maintenance on the control head.

Integrated communications

Three types of interfaces can connect ThinkTop to any PLC system and may be used in any combination:

- Digital interfaces

- AS-Interface (with 31 nodes or 62 nodes)

- DeviceNet interface (with 63 nodes)

Ease of installation

ThinkTop fits onto all Alfa Laval sanitary actuators equipped with mushrooms. Installation is straightforward; no special expertise, adapters or tools are required. To initiate manual setup, simply press the push-button startup sequence. Or set up without dismantling the control head using the optional IR keypad for remote control.

To learn more, click here: ThinkTop setup utilising IR keypad.pdf - ThinkTop setup utilising local I and II keys.pdf