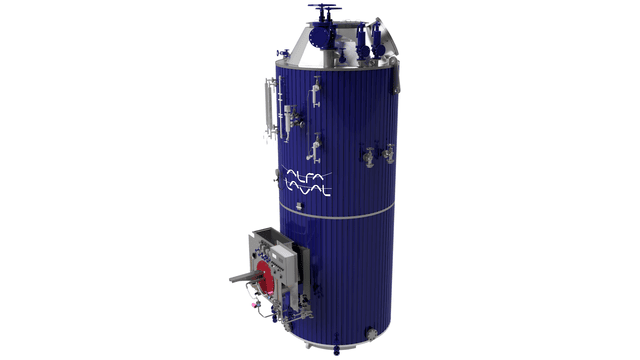

Aalborg OM-TCi

Aalborg OM-TCi is a vertical cylindrical steam or hot water boiler with a high thermal efficiency in the capacity range of 8,000 - 20,000 kg/h. The standard boiler can be fired with gas and various fuels, including methanol and biofuels. The boiler can optionally be fitted with electrical steam generation with shore-power and clean electricity.

High efficiency boiler with reduced emissions for a variety of fuels

- High thermal efficiency range 89 - 92% with low fuel consumption as a standard concept

- Thermal efficiency can be further improved up to 93 - 96 % (LHV) by adding an external economizer

- The standard boiler can be fired with gas and various fuels, like methanol and biofuels.

- Option for electrical steam generation with shore-power and clean electricity

- Proven design, ready to install and easy to operate and clean

Aalborg OM-TCi fired steam boiler has been developed based on our proven technology and long experience. The upgraded thermal design with optimized flue gas oxygen content ensures a total efficiency of 89–92% depending on boiler load conditions, which is on average 6% above the typical boilers in this capacity range. This means less fuel consumption and lower CO2 and NOx emission levels. As an example, on a 16,000 kg/h boiler operating 5,000 hours at 75% load every year, this means circa USD170,000 saved on fuel cost annually (at the fuel price of 650 USD/ton).

Thermal efficiency and savings can be further improved using Aalborg Micro as an external exhaust gas economizer reducing the use of the fired marine boiler by recovering heat energy that otherwise would be lost through the engine exhaust gas.

Service

We provide full support for our fired boilers. Our support covers their entire life cycle, beginning with design, installation and commissioning and extending past warranty throughout the service life.

Alfa Laval Service Agreements will help the operators of the systems. A fixed-period Service Agreement makes operation planning and cost projections more secure. A well-crafted maintenance strategy offers transparent cost control and safeguards performance, lengthening your equipment’s lifespan and reducing your total operating costs. Preventive maintenance is the key to reliable performance. Our Preventive Maintenance Programme comprises annual and 30-month services that comply with regulatory inspection schedules.

How it works

Furnace

Aalborg OM-TCi consists of a large furnace with gas-tight membrane walls. A sufficient number of downcomers ensures safe natural circulation, and adequate furnace dimensioning guarantees good combustion and low emission, moderate loading and low material stresses.

Convection part

A cylindrical shell surrounds the smoke tubes and the water/steam space. These smoke tubes have enhanced heat transfer features guaranteeing low exhaust gas temperature and thus high efficiency.

Burner & Control System

The boiler will be delivered with a multi-fuel burner, which is designed to automatically modulate according to the system’s heat demand. The burner is designed for a high turndown ratio with complete combustion at low oxygen levels. To ensure optimal combustion, pressurized air or steam is used as an atomizing media. The burner adjusts automatically, but the operator can switch to manual control if needed. The burner system allows the use of various alternative fuels, as well as the combustion of boil-off gas from gaseous fuels (GCU functionality, gas combustion unit).

The burner and the boiler are controlled by a specifically designed and standardized control system, which is included in the delivery. This system consists of all the required components for the heat recovery system according to Alfa Laval standards, including the main control with HMI-panel located in each engine room. The control system enables connectivity and intelligent data collection, and it has the capacity for remote

support. In systems with two engine rooms, each has its own control system, but they communicate and work seamlessly together, enabling flexible operating modes.

Design data

· Thermal output: up to 14 MW

· Steam capacity: 8,000 - 20,000 kg/h

· Design pressure: 10 bar(g)