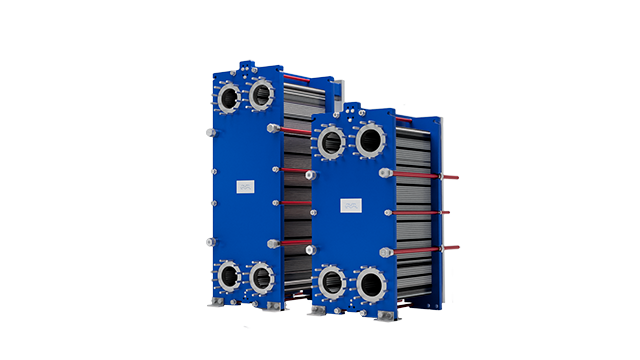

Industrial semi-welded line

Alfa Laval provides an extensive range of industrial semi-welded plate heat exchangers, designed for handling liquids and gases that are incompatible with standard gaskets or require operation at higher pressures. These heat exchangers are widely used in refrigeration applications, particularly for the evaporation and condensation of ammonia and CO2 for their exceptional resistance to ice formation and fatigue stresses caused by pressure and temperature fluctuations.

Highly efficient and flexible

- Space-saving compact unit

- Low operating cost possible owing to superior energy efficiency and prolonged service intervals

- Safe and reliable sealing with no risk of cross-contamination

- Pressure and temperature fatigue resistant

Performs under pressure

Semi-welded heat exchangers offer superior efficiency, cost-effectiveness, and flexibility over shell-and-tube heat exchangers, making them a preferred choice in many industrial applications.

- Compact and Space-Saving: Semi-welded heat exchangers are significantly smaller and lighter compared to shell-and-tube heat exchangers, making them ideal for installations with limited space. Their modular design also allows for easy expansion or modification to meet changing thermal requirements

- Easier Maintenance and Flexibility: While the welded sections provide durability, the gasketed side allows for easier cleaning, inspection, and plate replacement. This combination ensures long-term reliability and reduces downtime.

- Energy Efficiency and Cost Savings: Semi-welded heat exchangers are designed to minimize energy consumption and operational costs. Their high heat transfer efficiency and compact design reduce both initial and ongoing expenses, including pump power and maintenance costs.

What make our plate heat exchangers so reliable, efficient and serviceable?

Equipped with well-designed features that make a difference, Alfa Laval Industrial semi-welded line of heat exchangers are easy to maintain and have a long service life.

Uniport™

Uniport™

two innovations in one

High performance gasket sealing for high-pressure

RefTight™

RefTight™

sealing system

High performance gasket sealing for high-pressure duties

CurveFlow™

CurveFlow™

distribution area

Improves media flow and minimizes risk of fouling.

GasketGuard™

GasketGuard™

groove protection

Extended gasket lifetime through innovative protection.

OmegaPort™

OmegaPort™

noncircular port holes

Enhances media flow and thermal efficiency.

ClipGrip™

ClipGrip™

gasket attachment

Ensures perfect seal and trouble-free maintenance.

Selected Industrial Semi-welded heat exchanger stories

Victoria, Australia

The Carwarp project of RayGen comprises 4 MW solar power plus a 3MW/50MWh ETS system that will save 10,000 tonnes CO2 emissions per year and provide renewable electricity day and night to approximately 1,000 homes. >> Read more.

Alfa Laval walks the talk

An ammonia heat pump absorbs the waste heat from the cooling system of the plate pressing operation in the Alfa Laval factory. Benefitting plate heat exchangers, it contains an ammonia charge of only 40 kg for a capacity of 827 kW with a COP of 7. >> Read more about the case.

Baiyin, China

A sulphuric acid plant in Northwest China captures low-grade heat for re-use. In winter, all the recovered low-grade heat could be put back into their system with 30% being used in production and the remaining 70% going to space heating. >> Read more.

Odense, Denmark

Alfa Laval is supplying the evaporators, condensers, subcoolers and oil coolers to the heat pumps. The impact of the facility’s heat recovery infrastructure will help recover 100,000 MWh of energy per year – enough to warm some 7,000 homes. >>read more about waste heat from the leading social media giant's data centre.

Thessaly, Greece

The final plant design resulted in a total ammonia charge for the plant of only 680 kg including the externally placed evaporative condensers, that hold 200 kg each. In total, the higher energy efficiency compared with a conventional system saves some 340 MWh/year and reduces the indirect CO2 emission of appr. 300 ton/year. >> Read more.

Bradford, England

The two plate heat exchangers handle a total duty of 1500 kW and are part of a central cooling system that feeds unit coolers to provide direct cooling to the main produce storage area and subsidiary section for meat and fish. >> Read more.

How it works

The sealing between the plates on the Industrial semi-welded line alternates between laser welds and gaskets. The laser welded channel allows use of fluids that are not compatible with normal gaskets and also allows for higher design pressure than fully gasketed plate-and-frame heat exchangers.

T25-tailored to the new energy landscape

The urge for decarbonizing and renewable solutions is therefore bigger than ever. Alfa Laval semi-welded technology possesses unique features and characteristics that suit several emerging clean applications, such as green hydrogen, industrial heat pumps and energy storage, as well as existing traditional applications.

Plate heat exchanger portfolio

For 90 years, Alfa Laval has been developing plate heat exchanger technology tailored to our customers’ applications. Today we offer the market’s most comprehensive portfolio of plate heat exchangers to cover the widest range of needs.