DM

The Alfa Laval DM is a single-pass dry expansion evaporator for commercial and industrial refrigeration cooling for medium-temperature applications with evaporation temperatures in the range of -10 ÷ -20°C. DM is optimized for R134a and R407F refrigerants at medium pressures (21.5 barg). Capacity range 100 - 800 kW. PED/CE, ASME, EAC, SELO, DNV and other major marine approvals are available. The Alfa Laval DM replaces the Alfa Laval Dryplus-3 product line for negative evaporation temperature.

The Alfa Laval DM model is a dry-expansion shell-and-tube evaporator developed for medium temperature refrigeration applications.The DM design is optimized for R407F and R134a refrigerants, but can also be utilized with R404A and R507.

Application

The Alfa Laval DM evaporator has been developed for commercial and industrial refrigeration applications at medium temperatures ( -2°C to + 4°C), for supermarket food storage cooling or for industrial process cooling. These applications typically demand evaporation temperatures in the range of -10 to -20°C depending on the system efficiency and brines, such as propylene and ethylene glycols.

Technology

The Alfa Laval DM design is optimized for R407F and R134a refrigerants, but it can also be utilized with R404A and R507. With its innovative single-pass counter-current design, Alfa Laval's DM shell-and-tube evaporator series guarantees maximum efficiency, low cost and a new level of competitiveness.

Features

- The new design is optimized for R134a and R407F refrigerants in order to comply with future EU's regulations which will phase out refrigerants, such as R404A and R507 in 2017 (GWP > 2500).

- Very good thermal performance is achieved thanks to a patented and dedicated distribution system and new baffles, which minimize the shell bypass.

- Very efficient single-pass, counter-current design provides the best possible performance. Moreover, exchange tubes with an inner grooved pattern maximize the heat transfer coefficient and limit the negative effects of pressure drop.

- No safety margin is required for thermal sizing of the DM evaporator, which is generally recommended for other evaporators (Dryplus-3 and Dryplus-E) in Alfa Laval smarTube user guidelines.

Alfa Laval DM dry-expansion evaporator supply and delivery

The Alfa Laval DM evaporator is available in several different models with capacities up to 1.000 kW (medium temperature).

Benefits

- Compact design vs equivalent products in the market

- Performance guarantee by Alfa Laval lab test

- Low environmental impact: CO2 emission -52% vs equivalent products in the market

- Configurable online: contact Alfa Laval local sales organization to get the login

Options

- ASME, EAC, SELO, DNV and other major marine approvals available upon request

- Mounting feet

- Vic-Flanges

- Insulation

How it works

Construction

The Alfa Laval DM dry-expansion evaporator consists of a shell (pressure vessel) containing a single-pass straight tube bundle with inner-finned tubes. Developed for medium-temperature refrigeration applications, this new design is optimized for R134a and R407F refrigerants.

Operating principle

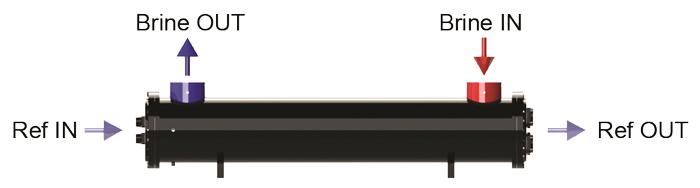

The Alfa Laval DM dry-expansion evaporator uses the well-known shell-and-tube heat exchanger principle to achieve the desired effect. The primary fluid, or refrigerant, flows through the tubes, while the secondary fluid (normally water or anti-freeze brine) flows over the tubes (through the shell) in order to bring about heat transfer from one fluid to the other.

The two-phase refrigerant flows through the expansion valve into the evaporator. It then continues to flow inside the tubes and evaporates as it absorbs heat from the surrounding secondary fluid, which is cooled down by this heat loss.

To achieve the most efficient cooling possible, the refrigerant is superheated in the final portion of the tube run to ensure that it reaches the compressor in vapour form. Specially designed baffles on the shell side boost heat transfer efficiency further.