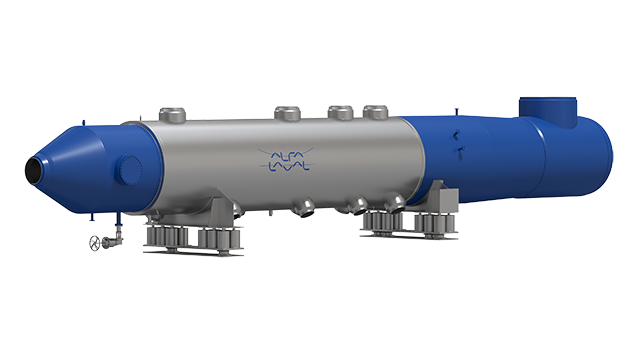

Process shell-and-tube heat exchangers

The Alfa Laval Olmi range of customized heat exchangers is designed and built for the toughest applications in chemical processing industries, oil & gas production and power stations. These units maximize plant sustainability through low service requirements and exceptional reliability, resulting in competitive total cost of ownership and trouble-free operation. And with our extensive offer of services, we can help you optimize operation throughout the entire product lifetime.

Solid performance

- Fully customized to your requirements

- Maximum uptime under the toughest operating conditions

- High energy efficiency

- Low service requirements

- Extensive service network

A complete service partner

With Alfa Laval as your partner you have full support from our experienced service teams around the world. We offer a wide range of services for process shell-and-tube heat exchangers, regardless of manufacturer. Our scope includes everything from regular maintenance to training, performance audits and upgrades.

Documents

Certificates

Alfa Laval Olmi quench exchangers

Quench exchangers are core components in ethylene plants. These units operate under extremely tough conditions and are exposed to high flows of hot gas containing coke particles. Thanks to their unique designs, Alfa Laval quench exchangers are much more resistant to erosion, fouling, fatigue and corrosion than traditional quench exchangers.

Alfa Laval offers three different models of quench exchangers:

- Alfa Laval Olmi Primary Quench Exchanger S&T Type

- Alfa Laval Olmi Primary Quench Exchanger Double-pipe Type

- Alfa Laval Olmi Secondary and Tertiary Quench Exchanger

Alfa Laval Olmi process shell-and-tube heat exchangers

Alfa Laval Olmi process shell-and-tube heat exchangers

Alfa Laval Olmi process shell-and-tube heat exchangers are used for demanding heat transfer duties at refineries, power plants and chemical processing industries all over the world.

We design and manufacture heat transfer solutions that are fully tailored to your requirements, e.g. with the ability to withstand extreme temperatures and pressures or corrosive process media. Our expertise in heat transfer, metallurgy and high-quality manufacturing ensure you get a shell-and-tube heat exchanger that will deliver high performance, reliable uptime and low operating costs for many years.

Alfa Laval Olmi process gas boilers

Alfa Laval Olmi process gas boilers are optimized for maximum performance and reliability. Our thermal and metallurgic experts ensure you get a complete system that suits your needs perfectly. We have long experience from supplying process gas boilers for some of the most demanding applications, such as steam methane reforming.

We offer three types of process gas boilers:

- Alfa Laval Olmi PGB package

- Alfa Laval Olmi Reforming Gas Boiler

- Alfa Laval Olmi Synthesis Loop Gas Boiler

Engineering expertise

Choosing Alfa Laval means you have the full backing of our application, thermal and mechanical design experts who will support you from the initial idea stage and advise you on a wide range of topics. They are used to handling the most complex heat exchanger design challenges, and in close cooperation with our welding and manufacturing teams they ensure you get a solution that offers maximum reliability, high performance and low investment costs.

Metallurgy

Material selection is a key stage when designing a heat exchanger operating at high temperatures and pressures. Choosing the right material is essential for reliable operation, long life span and low service costs. Based on your specific conditions, our metallurgy experts recommend materials that offer an optimum balance between CAPEX and OPEX.

Built to last

The quality and operational reliability of our products is our first priority. We know that even a minor imperfection in a weld joint in a high-pressure heat exchanger can cause costly breakdowns. When you install one of our heat exchangers you can rest assured that nothing has been left to chance and that every detail is of the highest quality.

Welding

Welding is one of our core competencies and we continuously invest in staff training, certifications and new welding technology to ensure the highest weld quality.

Testing

Every heat exchanger that leaves our workshop has been thoroughly tested using a range of non-destructive tests, such as ultrasonic NDE, x-ray/gamma ray tests, hydro tests, helium and dye penetrant tests. Our inspectors are certified according to NDE Level II and III according to SNT TC1A and EN9712.

Capacity for large units

In our 65,000 m2 workshop we have the capacity to manufacture large-scale heat exchangers.

ALOnsite - Qualified support at your facility

Improving sustainability with welded solutions

Unique features

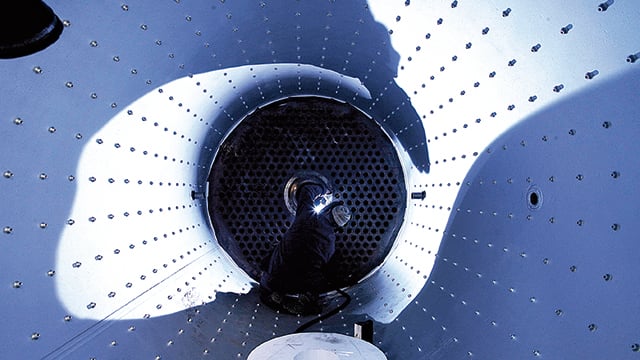

OptiForm

Ensuring reliable operation

The unique OptiForm tube sheet design gives Alfa Laval Olmi heat exchangers high resistance to erosion, corrosion and weld overheating.

The first section of the tubes is an integral part of the tube sheet, machined after the plate has been forged. This means the welds connecting the tubes to the tube sheet are placed in the cooling medium, which protects them from overheating as well as impacting particles in the hot gas stream.

The tube sheet surface is protected against the erosive hot gas by an Inconel layer, and the thin base plate allows for effective cooling and a low surface temperature. The result of these design innovations is exceptional durability and operating reliability compared to traditional tube sheets.

ProShield

Secure uptime

The ProShield inlet on our double-pipe type quench exchanger does not suffer from the problems with coke growth and cracks in the Y inlet commonly found in similar quench exchangers.

The highly effective cooling of the inlet and the short residence time dramatically reduce the difference in thermal expansion between the inner and the outer pipe, and the risk of fatigue cracks in the Y inlet.

The superior cooling also eliminates the need for a thermal sleeve and does away with problems with coke migration and growth.

The end result is a quench exchanger that offers long and reliable uptime in combination with low service requirements.

Case story

First-class service support

See how Alfa Laval’s service specialists helped technicians at the Midor refinery in Egypt to perform service on four feed/effluent heat exchangers.

Keep updated

Follow us on LinkedIn to stay updated on the latest news from Alfa Laval.

Talk to an expert

We will be happy to discuss the benefits of an Alfa Laval Olmi heat exchanger and to show how we can help improve your operation.