Equipment Audit for Energy

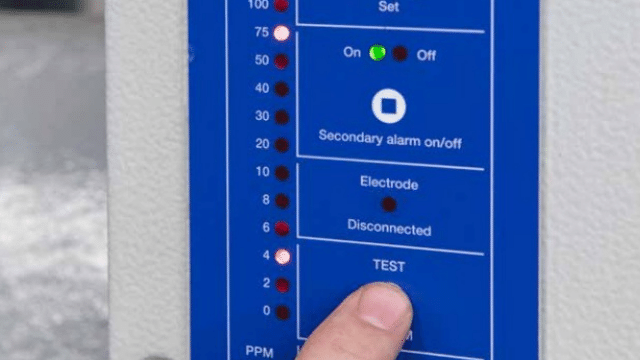

Break down maintenance, sometimes known as ‘run to failure’, is a common strategy for bringing down costs. While useful in certain cases, its limitations make it a false economy for companies looking for a long-term competitive advantage. In today’s world, where even minor stoppages can be the difference between success and failure, it makes sense to keep key pieces of equipment fully functional and operating at their best. By regular and planned maintenance, equipment performance is preserved, and operations kept trouble-free and predictable. Prevent future issues in your plant with an Alfa Laval equipment audit. Our highly qualified Service Engineers with extensive equipment knowledge will help in identifying potential equipment problems, so that you can take proactive actions to avoid unexpected breakdowns, costly downtime and major losses in production.

Key benefits

- Secured plant uptime and productivity

- Prevention of safety issues

- Optimized maintenance plans

- Improved control of maintenance budgets

- Increased equipment lifetime

- Optimized performance

Equipment list

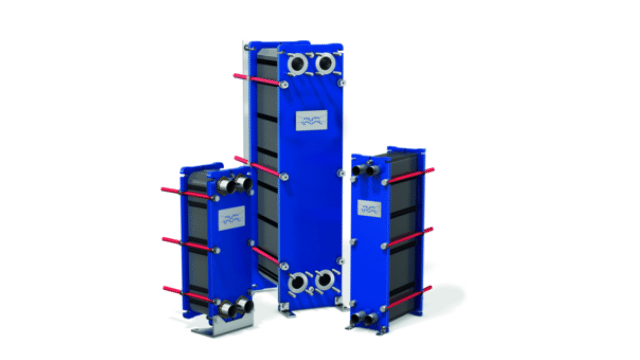

Plate heat exchangers

Spiral welded heat exchangers

Compabloc welded plate heat exchangers

Decanter centrifuge

Alfa Laval filters (ALF)

Freshwater generators

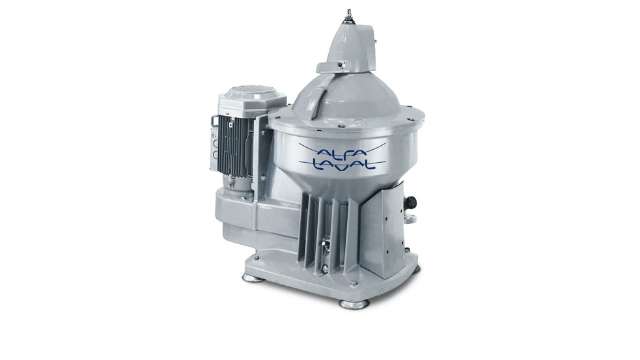

High speed centrifuge separators