Expert insights into your Alfa Laval filter’s health

Alfa Laval Filter (ALF) is the perfect companion to utility heat exchangers that use sea, lake or river water as the cooling medium. ALF filters remove all debris and marine life that can cause clogging, reducing the risk of unplanned downtime and prolonging heat exchanger service intervals. A poorly functioning filter may affect thermal performance of plate heat exchangers, lead to costly downtime and losses in production. Performing a condition audit will give you insights about the actual condition of your Alfa Laval filter. Our specialists can find out the state of the equipment in terms of mechanical condition, cleaning requirements or repair needs. With this regular and proactive maintenance, equipment performance is preserved, and operations kept trouble-free and predictable.

Key benefits:

- Secure operation

- Avoid unplanned stops for maintenance/repair

- Optimize maintenance plans

- Identify strategic spare parts

Lean more:

When to use:

When you change process conditions

When equipment is critical in your process

For older installations

Who does the audit?

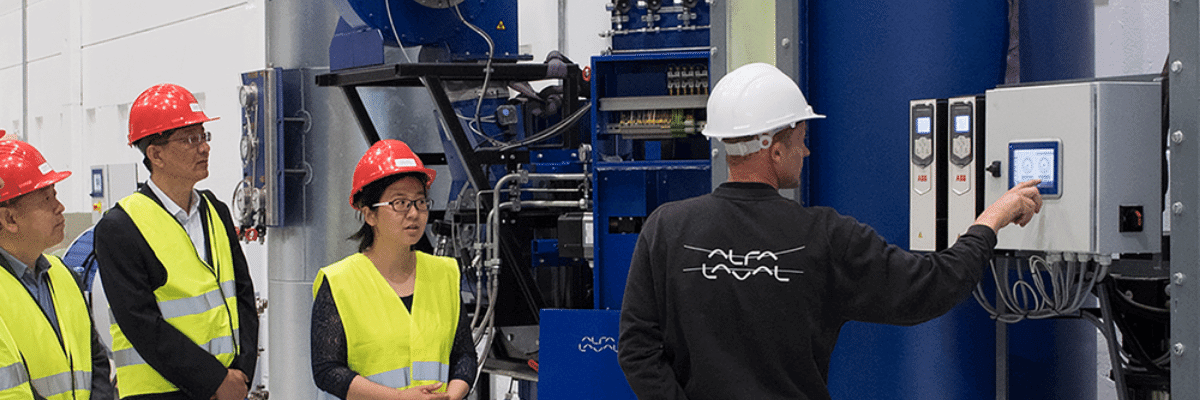

An Alfa Laval Condition Audit can be performed onsite by highly experienced Alfa Laval service engineers with deep Alfa Laval filter knowledge.

How do you get the results?

Our service experts will provide a comprehensive report with all findings and recommendations.