Expert insights into your drum thickener’s health

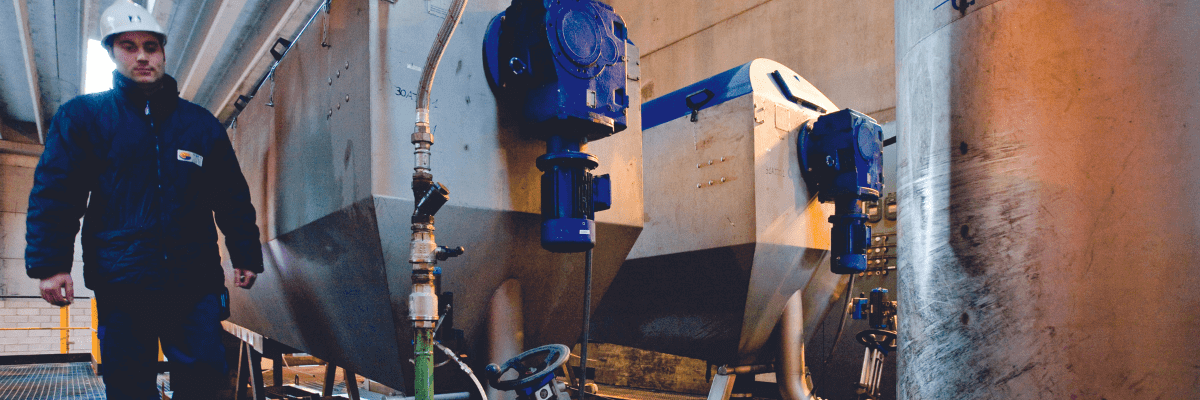

Drum thickeners are used for sludge thickening before storage and transportation, or for optimizing sludge for subsequent processes or dewatering. A poorly functioning drum thickener may affect sludge quality, safety and production. Knowing the true condition of the drum thickener components can reduce the risk of unplanned downtime and prolong service intervals.

Performing a condition audit will give you insights about the actual condition of your Alfa Laval drum thickener.

Areas of the drum thickener to be inspected visually:

- Flocculation reactor, Mixing Valve, Feed pipe, drum internals, gear box, wash water spray bar that are applicable to your equipment

- Bearings, Filter Cloth and other Wear components

- Electrical wiring, motors, drive coupling, switches

With this regular and proactive maintenance, equipment performance is preserved, and operations kept trouble-free and predictable.

Key benefits

Knowing the state of your Alfa Laval drum thickener makes you able to:

- Secure reliable operation

- Avoid unplanned stops for maintenance/ repair

- Avoid safety issues

- Discuss maintenance plans

- Have peace of mind

When is the audit right for me?

Equipment audit should be considered when any of the below circumstances exist:

- Use of abrasive and harsh influent

- Equipment is used in critical process

- Changing process conditions

- Older installations

Who does the audit?

Our certified and experienced engineers inspect your Alfa Laval drum thickener.

How do you get the results?

After the audit, you will get an analysis of operating conditions with recommendations for need of maintenance, repair, or upgrade.